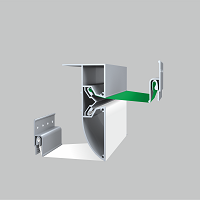

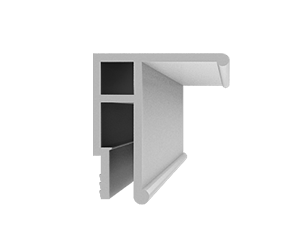

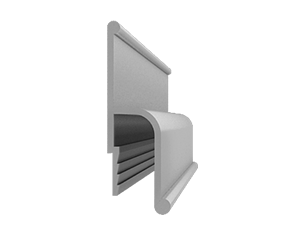

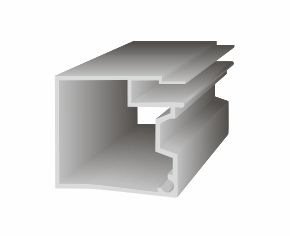

No. 30 Aluminum track for multi-level stretch ceilings

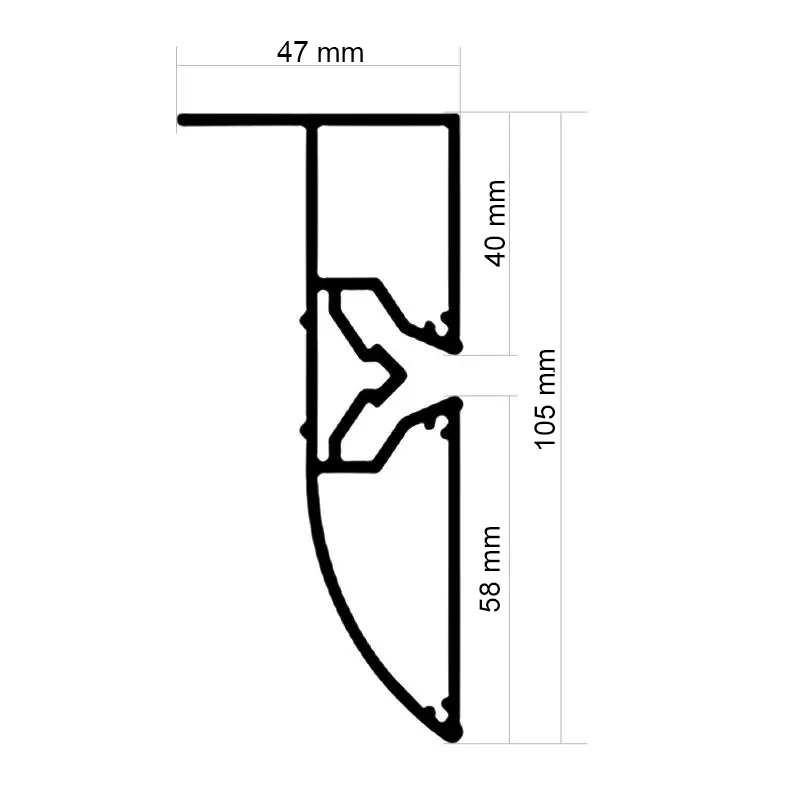

| Dimensions | 200 × 47 × 105 cm |

|---|---|

| material | Aluminum |

Fixed-height metal structures can be made based on Track No 30. This track is used for straight and curved ceiling structures where the ceiling height level changes at 58 mm. Using this track, one can build a structure for a ceiling with different height levels on site or choose a prefabricated ready-to-install structure instead. Covering

strip 15 can be used.

• Min height loss 10,5 cm

• Ceiling height level change 5,8 cm

• The upper ceiling level matches with wall track

• Perfect joining of track elements using inserts

• Min bending radius is 150mm

• Reinforced track edge (ledge)

• Dismounting without any mechanical damage

• The track is available in 2 lm sections

General operational sequence with Track No 30 structures

1. Individual track elements are joined using inserts (pins). The inserts are driven through connections until only a 5-6-mm end protrudes outside.

2. Connection joints between track elements are additionally secured with aluminium bar strips 10-12 cm long and self-tapping screws for metal with pressure pads. It is recommended that each strip is secured with at least four self-tapping screws. Use at least 2 strips per joint (on the front and the back of the track) to ensure secure holding.

3. There are two methods to attach a structure made using Track No 30 to the original ceiling:

a. The structure can be attached directly onto the original ceiling. Use the horizontal side flange of the track to secure the structure onto the original ceiling. The method is to be used when the original ceiling is even and with no ceiling height level changes over it.

b. The structure can also be attached using shelf brackets or seat angles. This method is used when the original ceiling deviates considerably from the horizontal plane. Pieces of the track horizontal side flange need to be removed in points where the shelf brackets will be attached. The shelf brackets or seat angles are secured to the original ceiling with a pitch of 40-60 cm following the structure contour. Then the structure is levelled horizontally and is secured with self-tapping screws to the brackets.

Procedure for straight-line structure installation using Track No 30

In case one is to assemble a structure for a ceiling with straight-line ceiling height level changes on their own, one needs to:

1. Make corners (inner and outer)

2. Prepare straight sections of the lengths required.

3. Put all the structural elements together.

If a Track No 30-based structure runs against a wall, follow the wall track installation procedure below to produce different height levels:

Assembly of curved structures constructed using Track No 30

Curved structures for installation of different height level ceilings are made from notched Tracks No 30.

The notches make it possible to:

• bend the track both ways, i.e. inward and outward;

• connect pieces of different curvature;

• smoothly change curvature of sections.

Combining curved and straight sections provides the possibility to shape your ceiling levels almost in any way required.

When working with a notched track, make sure you secure it with a binding band (aluminium band 15 mm wide and about 2 mm thick). The band is attached to the notched side of the track with self-tapping screws with a pitch of 3 notches. However, the pitch should be smaller on the ends.

The recommended minimum curve radius of a finished structure is 150 mm.

Structure elements are joined using inserts (pins) with an additional piece of the aluminium binding band.

Using notched No 30 Tracks, you can construct a curve structure on site by yourself. Otherwise, it is possible to order a pre-fabricated ready-to-install structure.

Ordering a pre-fabricated structure significantly improves the rate and quality of installation works, and eliminates the necessity to construct the structure on site. When ordering a ready-to-install structure, all you have to do on the Customer’s premises is put pre-fabricated elements together to assemble the structure.